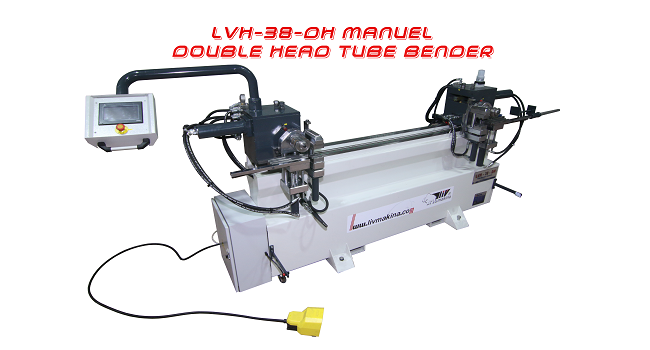

LVH-38-DH TUBE BENDING MACHINE

- ⚡ Manual ( LVH-38-DH ) , servo adjusment ( LVH-38-DH-NC1 ) and Servo + Rotating 3 axıs bendıng system ( LVH-38-DH-NC2 )

- ⚡ Foot switch has auto start, emergency stop, emergency-stop and going on function, it has high safety.

- ⚡ Interactive PLC touch screen offers easy access to manual modes.

- ⚡ All the parts, structure and characters are the standard of mechanical engineering from Europe.

- ⚡System diagnostics and multiple language capability.

- ⚡One-touch automatic bending mode wıth foot pedal.

- ⚡Overseas after service center available in some region.

- ⚡ It is protected under the useful model with the patent number 2017/11840.

- ⚡ All Electronic Parts, Servo Motors OMRON JAPAN.

- ⚡ We are using Italian Zed & Motovario gearbox

DOUBLE HEAD PIPE BENDING MACHINE |

LVH-38-DH MANUAL |

LVH 38 DH NC1 SERVO SYSTEM ( OMRON SYSTEM JAPAN ) |

LVH 38 DH NC2 SERVO+ROTATING SYSTEM ( 3 AXIS BENDING ) |

|---|---|---|---|

| Maksimum Bending Capability | Ø32 mm X 2 mm | Ø32 mm X 2 mm | Ø32 mm X 2 mm |

| Maksimum Mold Size | 250 mm | 250 mm | 250 mm |

| Minimum Mold Size | 90 mm | 90 mm | 90 mm |

| Clamp System | Hydraulic | Hydraulic | Hydraulic |

| Bending System | Hydraulic | Hydraulic | Hydraulic |

| Control Panel | PLC+ DIGITAL SCREEN | PLC+ DIGITAL SCREEN | PLC+ DIGITAL SCREEN |

| Machine Sizes | 2500MM X 1500 MM X 1500 MM 1300 KGS |

2500MM X 1500 MM X 1500 MM 1300 KGS |

2500MM X 1500 MM X 1500 MM 1300 KGS |

| User Guide | (✓) | (✓) | (✓) |

| Electric Scheme | (✓) | (✓) | (✓) |

| Spare Part | (✓) | (✓) | (✓) |

| DISPLAY ANGLE FEEDBACK | (✓) | (✓) | (✓) |

| Angle Registiration System | (X) | (X) | (✓) |

| Machine Installation Lessons | (✓) | (✓) | (✓) |

| Warranty | 12 Month | 12 Month | 12 Month |

| Settings the Bending Distance from the Display Screen |

(X) | (✓) | (✓) |

| Ethernet | (✓) | (✓) | (✓) |

| Free Mold | 1 Set | 1 Set | 1 Set |

| 3 AXIS BENDING | (X) | (X) | (✓) |

| Daily Production Retention | (✓) | (✓) | (✓) |

| Shows to Errors on Digital Monitor | (✓) | (✓) | (✓) |

Machine Features

- SAFETY is a prime concern with a machine that moves as quickly and quietly as a fully electric bender. Our fully electric cnc tube bender machines can integrate several emergency features such area scanners and light barrier fences.

- Fully-electric motion controls are extremely simple compared with previous technologies. Reduced and more efficient components mean lower friction and wear – allowing for a design with high output, efficiency, rigidity, wear resistance, reliability and operation safety.

- Productivity is boosted by shorter cycle times, low setup between projects, no adjustments during production, no wasted parts, energy cost reductions and low maintenance procedures.

- All machine movements are via electric servos. Part bend positions, tooling information, and power parameters are all saved together in the part program. When a job is repeated you simply mount the tools and recall the program. No futher mechanical adjustments are needed. This guarantees quick setup and changeover and provides lot to lot repeatability. It also eliminates the need for a bender set up specialist.

- We have reduced energy consumption with no reduction in bending capacity.

Question answer

Manufacturer warrants the products to be free from defects in material and workmanship for 12 months from the date of shipment to the original purchaser only. We will send parts (FREE) use DHL for your replacing. If the machine has worse running problems, we will send engineer to your factory for maintenance.

Machine should be placed in position and main power connected prior to setup and training at customer site. Customer should pay for travel plus related expenses (may include hotel, airfare, and rental car etc.) We also welcome customer send people here for training how to operate machines. Lead time: One week, and customer should pay all relative expenses by themselves.

1. Steel furniture, air conditioning, refrigeration, sanitary industry (for thin-walled tube, producing no wrinkle)

2. Automobile parts (brake tubing, bumpers, mufflers, exhaust pipes, car seat)

3. Motorcycle manufacturing, bicycle manufacturing (handlebars, frame), fitness equipment

4. Shipbuilding, boiler industry (for thick-walled tubes, to ensure bending ovality and thinning rate).

5.And other profile bendings..